Basketbol, futbol ve tenis kuponları hazırlamak için Bettilt bölümü aktif olarak kullanılıyor.

Her an erişim isteyen oyuncular için Bettilt uygulaması tasarlandı.

Canlı rulet oyunları, klasik masa oyunlarının dijital versiyonlarına göre daha interaktiftir; sanal bahis siteleri bu farkı hissettirir.

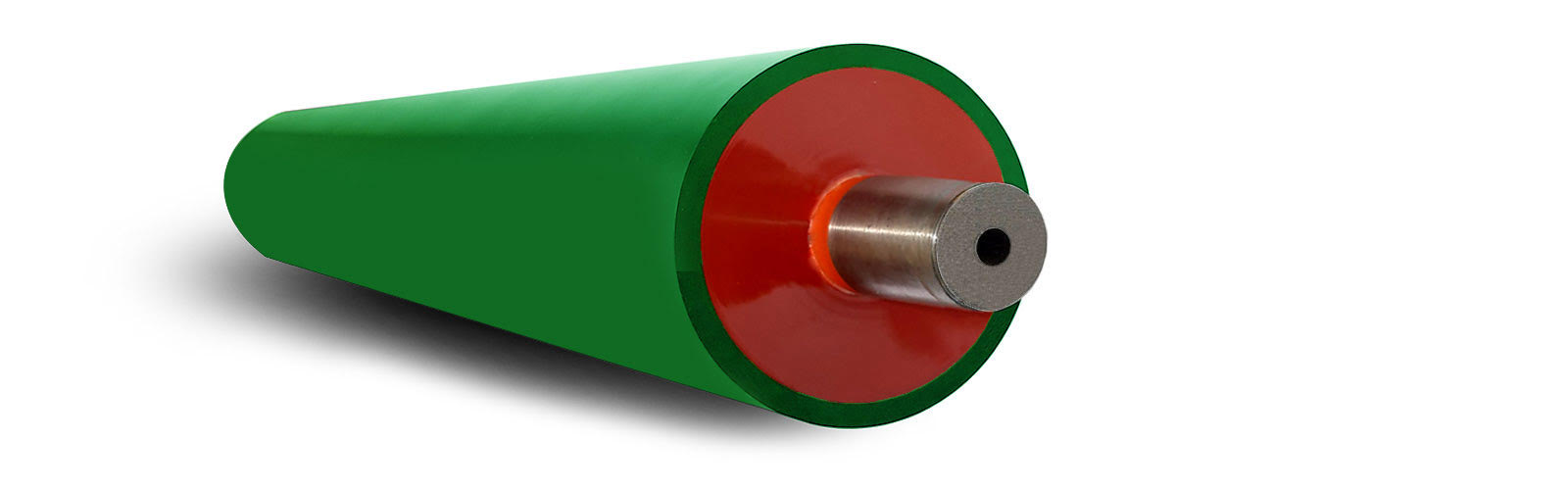

Rubber Covering - EPDM (Ethylene Propylene Diene Monomer)

Designed to meet the requirements of today’s industries such as printing, textile, steel, and paper.

EPDM compounds are produced In varying durometer hardness ranges Of 30 – 95 Shore A.

Due to its chemical structure, this polymer exerts excellent resistance to ozone and many other chemicals. this together with its ability to run at elevated temperatures makes this compound an ideal roller covering material for a wide range of applications such as coating rollers and flexographic printing.

The compound offers special grades for Laser Engraving, Anti Static, Peroxide or Sulphur, and Food Quality Types.

Rubber Covering is also offered for the following applications

EPDM Key Features & Benefits