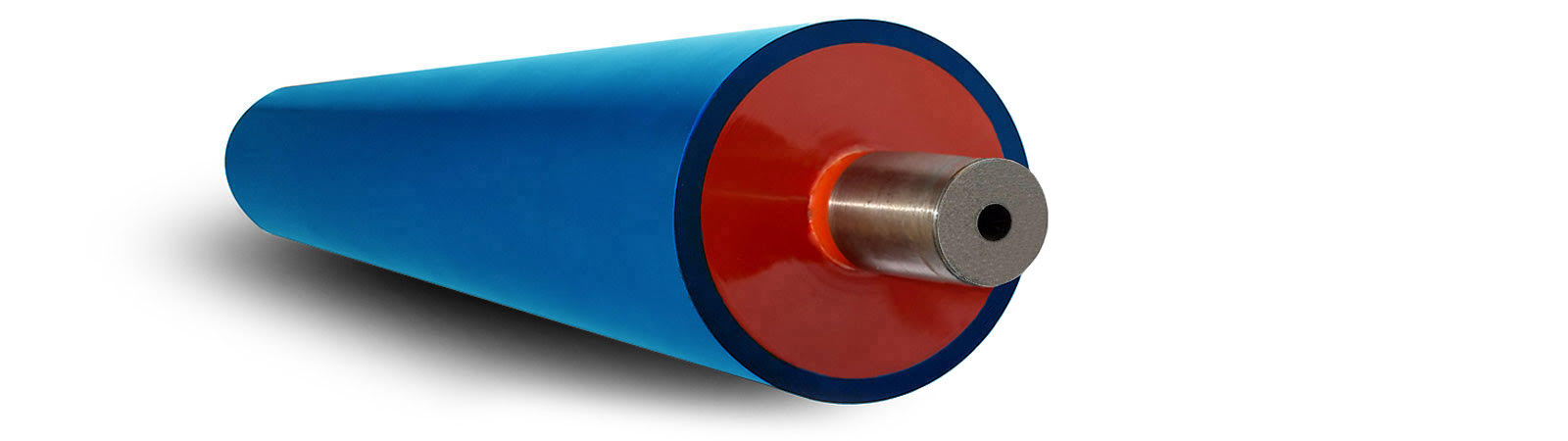

Rubber Covering - Hypalon

Designed to meet the requirements of today’s industries such as printing, textile, steel, and paper.

Hypalon compounds are produced In varying durometer hardness ranges of 35 – 95.

Hypalon is a Du Pont trade name for Chlorosulphonated Polyethylene (CSM). This polymer has been used in the roller covering industry for many years and the early difficulties with processing the material have now disappeared with the evolution of modern processing aids.

Hypalon compounds are used primarily where a combination of heat and chemical resistance is required such as laminating, film processing, steel and chemical treatment processes. High hardness grades 90-95 Shore A also exert good abrasion resistance and can withstand high roll loadings. The compound offers special grades such as Anti static types usually black but some colours are available on request. High Hardness Grade 90-95 Shore A and food quality types.

Hypalon Key Features & Benefits

- Rubber Covering – Dual Shore

- Rubber Covering – Silicone

- Rubber Covering – Nitrile

- Rubber Covering – Neoprene

- Rubber Covering – Natural Rubber Compounds

- Rubber Covering – Hypalon

- Rubber Covering – EPDM (Ethylene Propylene Diene Monomer)

- Rubber Covering – Electrostatic Assist

- Rubber Covering – Carboxylated Nitrile

- Rubber Covering