The Role of Furnishing Rollers in Consistent Coating and Finishing

In industries where coatings, inks or adhesives play a decisive role, the quality of application equipment directly influences the end result. Furnishing Rollers are central to this process. They’re designed to deliver a smooth, even layer across a wide range of substrates, ensuring that every product leaving the production line meets the same standard of quality.

To understand their value more fully, this blog explores why coating consistency matters, how technology has advanced the performance of furnishing rollers and the industries where they make the greatest impact.

Why Coating Consistency Matters

Inconsistent coatings can quickly lead to wasted material, rejected batches and rising costs. Uneven application also affects product performance, whether it is packaging that needs a reliable seal or textiles that require a uniform finish. Furnishing rollers reduce these risks by controlling the volume and distribution of coatings with precision. This reliability helps manufacturers maintain efficiency, minimise downtime and protect their reputation for consistent quality.

How Technology Has Improved Furnishing Rollers

Advances in engineering and laser technology have transformed the performance of furnishing rollers. Traditional methods often left small imperfections or required more frequent maintenance.

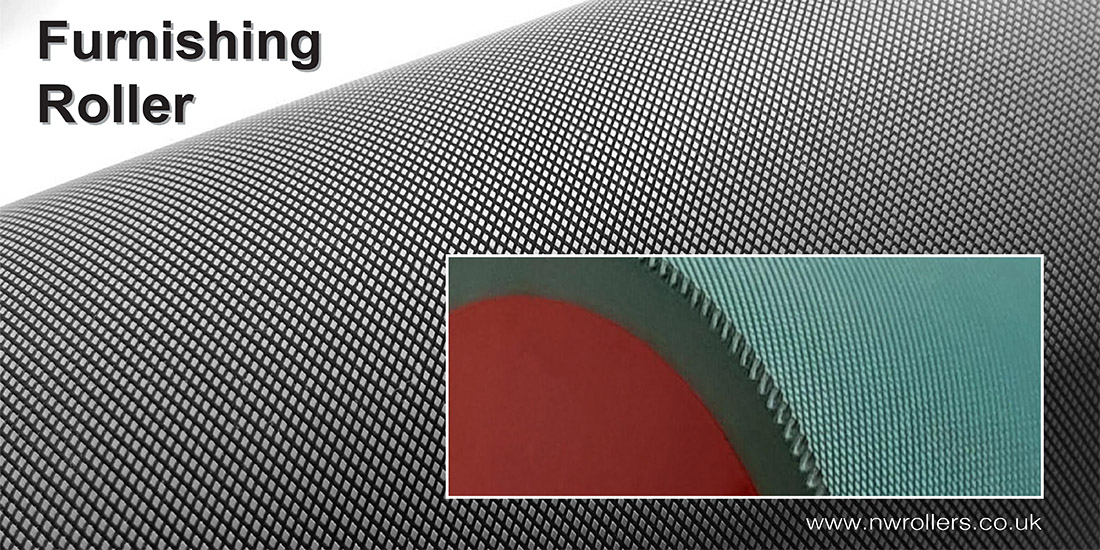

In contrast, modern rollers produced with in-the-round laser engraving offer accuracy that older methods struggled to deliver. The engraving process allows patterns to be cut to exact specifications, so coatings are applied evenly and remain consistent throughout long production runs.

At NW Rollers, the process begins with carefully engineered cores, followed by laser engraving, precision grinding and digital balancing. Each roller is manufactured to exact tolerances so that it can operate at high speeds without vibration or loss of accuracy. The result is a roller that supports longer runs, reduces waste, and consistently delivers high-definition results.

Applications Across Industries

Furnishing Rollers play a part in many different industries. Printers turn to them for even ink and coating transfer, which keeps colours consistent from the first sheet to the last. In laminating and textiles, the same precision ensures adhesives are applied smoothly without gaps or waste.

The same level of precision applies across all these uses, giving manufacturers confidence in every production run.

Technology That Raises the Standard

For businesses that rely on repeatable quality, the choice of rollers makes a direct difference to performance. Furnishing Rollers provide the accuracy and reliability needed to keep operations efficient and products consistent, supporting longer runs and reducing waste. When the right equipment is in place, manufacturers can focus on output and innovation rather than worrying about uneven finishes or rejected batches.

That’s where NW Rollers makes a difference. With decades of expertise and the UK’s most advanced engraving facilities, they supply solutions that give clients confidence in every result. আজ আমাদের সাথে যোগাযোগ করুন আরও জানতে।

by Scott Pendlebury

by Scott Pendlebury 25 September 2025

25 September 2025